Power-to-Gas

Hydrogen, power-to-gas and power-to-X technologies offer innovative solutions for the sustainable energy supply of the future. One particularly exciting approach is the conversion of biogas and biomethane into hydrogen. By reforming these gases, hydrogen can be produced, which can be used as a versatile energy source. This process enables the efficient utilisation of biogas and biomethane by converting them into a form that can be easily stored and transported.

Electrolysis - Wind Blows, Sun Shines - The Foundation for Hydrogen Production

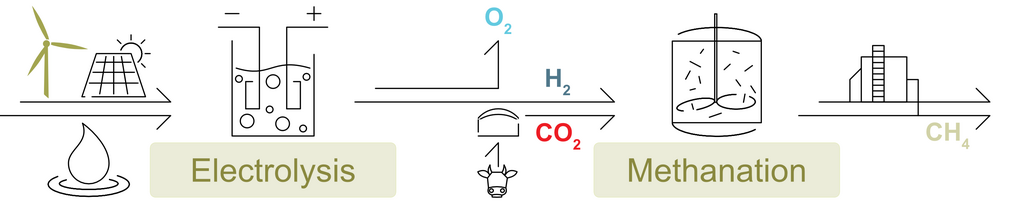

Instead of, for example, shutting down wind turbines, surplus electricity is used to produce green hydrogen via electrolysis. This hydrogen can be used directly as an energy carrier, transported, or stored. Injecting hydrogen into the natural gas grid and developing dedicated hydrogen networks are increasingly being promoted. Hydrogen can be utilized in fuel cells and engines for power generation or mobility. Additionally, hydrogen and its derivatives (e.g., ammonia and methanol) are vital raw materials for the steel and chemical industries. Furthermore, hydrogen can serve as a precursor for synthetic fuels (e-fuels).

Methanation - Producing Renewable or Green Gas (Electricity from Renewable Sources)

In methanation, hydrogen is converted into methane, binding CO2 in the process. This renewable methane (SNG) is of natural gas quality and can be used like natural gas or fed into the gas grid.

- Catalytic Methanation: Methane is produced through a technical process (Sabatier process) using a catalyst.

- Biological Methanation: Specialized microorganisms are used in bioreactors to produce methane.

The choice of method depends significantly on the scale and the planned CO2 source. Biogas or CO2-rich exhaust gas from a biogas upgrading plant can serve as CO2 sources for methanation, reducing emissions and eliminating the need for complex CO2 extraction from the atmosphere. In the case of biogas upgrading, a feed-in connection to the natural gas grid is already available, and the heat generated during methanation can be utilized. This increases the overall efficiency of the plant.

Reference Projects:

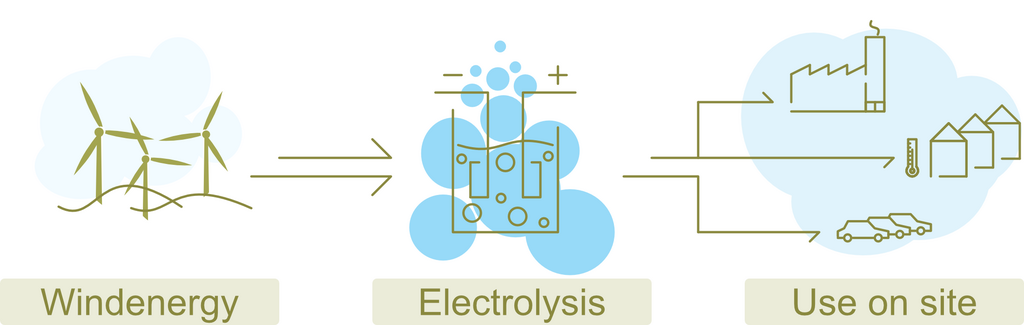

Electrolysis Staßfurt (Germany) 2023

- Energy Region Staßfurt: Hydrogen production from green electricity. The electrolyzer is powered exclusively and continuously by green electricity from the wind farm.

- Process technology: Water electrolysis system with 1 MW, based on the PEM (Proton Exchange Membrane) process.

- H2 utilization: Supplying a hydrogen filling station near the highway and injecting hydrogen into the natural gas grid.

- Hydrogen production: 1 MW electrical input; 130 tons/year of green hydrogen from wind power (wind farm).

- Client: Project consortium Energy Region Staßfurt.

2022:

- Member of the DVGW working group G471 "Net Cells".

- Consultation and concept development for achieving climate neutrality for an industrial site in Lower Saxony.

- Feasibility study and market analysis for the application of hydrogen and methanation at a biogas plant in Saxony-Anhalt.

- Research project: Paper-derived ceramic carriers for microreactors in the chemical-catalytic methanation of CO2 (P2G-CatCarrier).

2021:

- Tender for an electrolysis plant for a project in Lower Saxony.

- Participation in the ViridisH2 research project.

- Concept development for integrating Power-to-Gas into the heat and power supply of a facility in Lower Saxony.

2017/2018:

- Supervision of a bachelor's thesis on the topic:

- Power-to-Gas: Economic and technical possibilities and regulatory framework.

![[Translate to English:] Panorama Biogasanlage Dinteloord](/fileadmin/_processed_/6/7/csm_Dinteloord_Biogasanlage_800x200_9b09cdf979.jpg)

![[Translate to English:] Panorama Biogasnalage Anklam](/fileadmin/_processed_/d/9/csm_1731Anklamgesamt_800x200_7a54f43722.jpg)